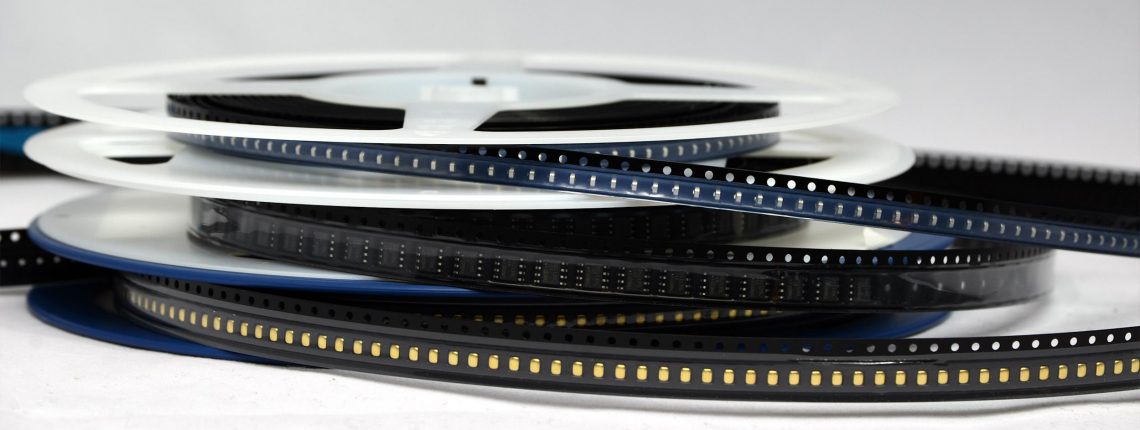

Component taping

As a service we provide component taping of standard size parts and the re-taping of parts from machine placement errors, both in small and large series.Based on samples and drawings, we provide the design and production of carrier tapes for special parts, as well as the taping of these parts.

Taping machine (for component reeling)

Model 1100 D is suitable for both hot and cold press foil taping. The large steel-covered work surface makes the process of taping easier.The setting of parameters is simple and user-friendly.The operator can easily adjust the tape/strap sizes, therefore, changing products is very fast.The products are easy to tape, the tape-transport is consistent.

Service of 1100 D:

- The locking mechanism works quietly and evenly

- Suitable for both hot and cold press (PSA) foil taping

- No dedicated tooling provides quick, easy changeovers

- Constantly adjustable for 8-72 mm carrier foils

- Large steel-covered work surface

- Smooth work surface to provide ease of placement into carrier pockets

- Fine-tuning options for positioning the cover tape precisely

- Programmable parts counter

- Easy to change speed

- 13” or 22” tape size

- Quality and variety

Carrier tapes:

- Wide range of standard sizes

- Designing and manufacturing of customized carrier tapes based on technical data and sample